Some of my latest projects

Helping out at The Wilkesboro Peach Festival in N.C.

Forged Bowie

Forged Bowie

This is a forged Bowie I made at the first of last year. The steel is 3/16″ 1095 steel with a 10″ blade, cherry handle scales and a gun blued finish. I have another Bowie in the works with 1/4″ 1080 and a 12″ blade. I’m going to work on some Bowie’s and other style knives with guards. I know my day job gets in the way sometimes. Sorry, I haven’t posted in a while.

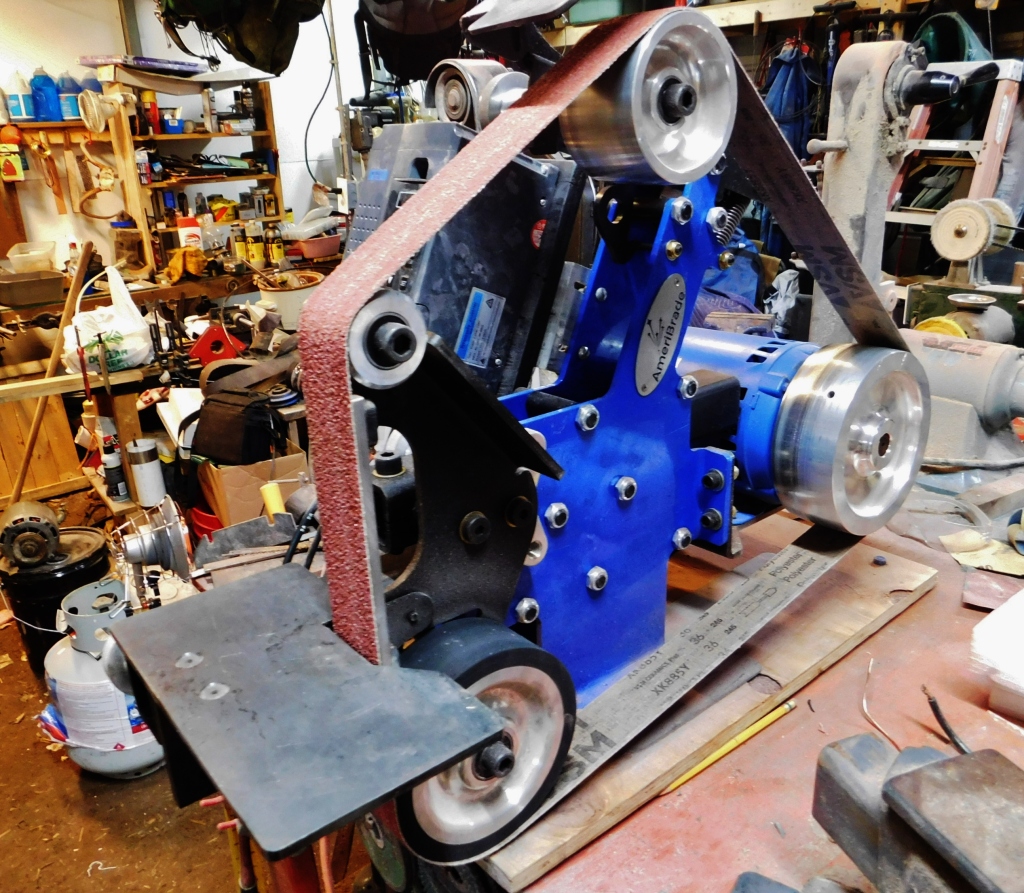

Powered shop and new grinder

Powered shop and new grinder

It has been a while since my last post. We have finally got our shop wired and fully powered. W have been running off of drop cords every since we started our shop in N.C. Our new grinder has a 3 phase 2 hp. motor with a vfd. The vfd converts the power and also adds the ability to run variable speed, as well as backward. We have given the new shop power a test run by starting 3 grinders at once. the lights went dim before with just one grinder. We have success. We are looking forward to the new grinder and full power